Proven Desiccant Rotors

When it comes to desiccant dehumidification rotors and cassettes, choose Rotor Source to manufacture highly proficient products. Rotors and cassettes are available in many different configurations to meet your air-drying and humidity-control needs.

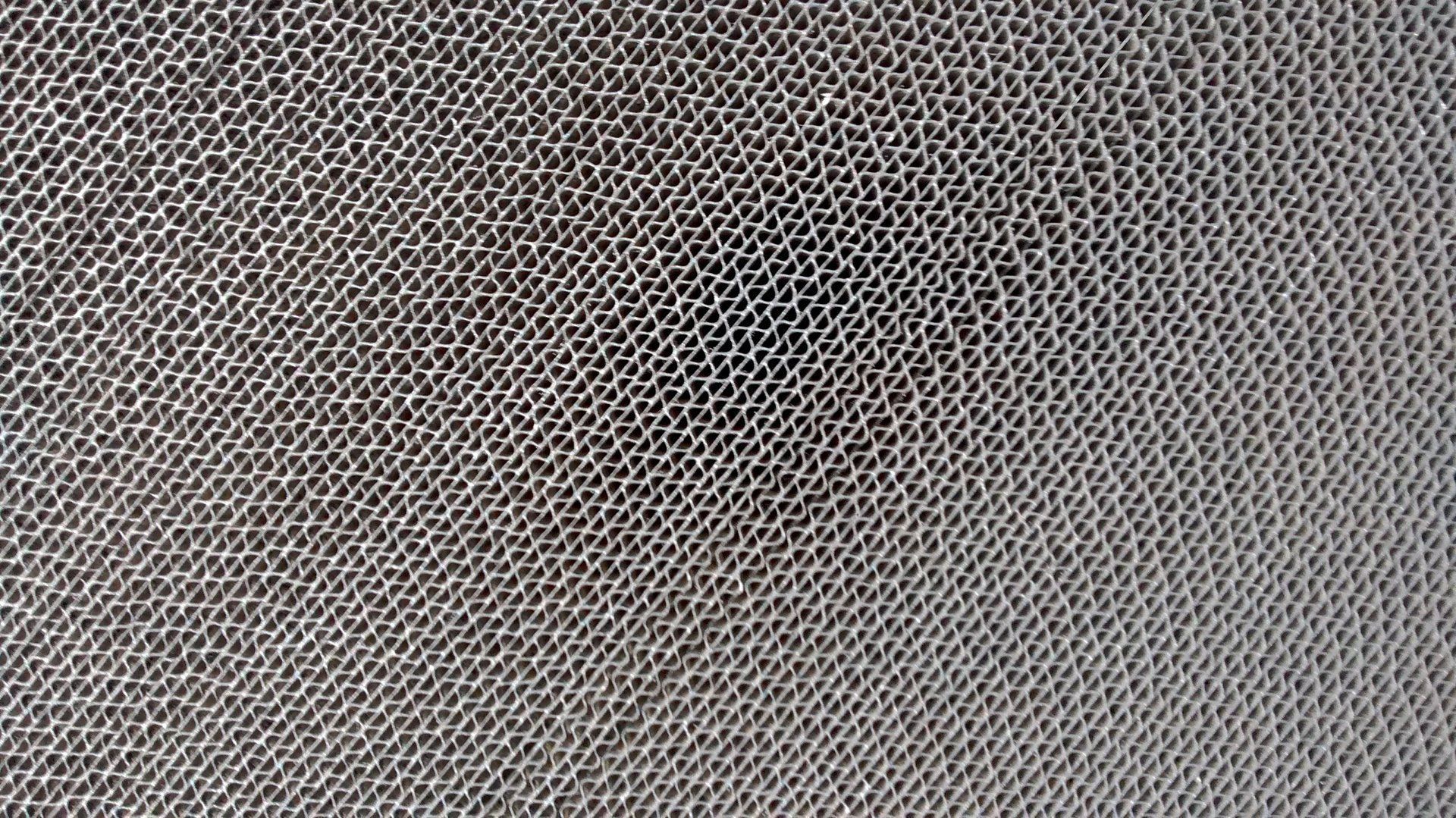

Our rotors are made of high-capacity substrates, including silica gel and molecular sieve desiccants, sitting in laser-cut aluminum housing for optimal quality. Our recore program has earned a reputation as a faster, more cost-effective way to replace any brand of desiccant dehumidification rotor.

Contact us today to request a quote from Rotor Source.

Dehumidification Rotors and Cassettes

- Inorganic media withstands high heat

- High capacity meets and exceeds the competition

- Lower pressure drop than the competition

- No-maintenance internal bearings

- Welded structure maintains tolerance

- Stainless-steel flange compatible with all seals

- Low-cost for industrial and commercial applications

- Standard sizes to 3.5-meter diameter – larger diameters available

- Standard depths include 100 mm, 200 mm, and 400 mm

- Available in non-standard sizes

- Complimentary performance software program

High-Capacity Dehumidification

- 98% inorganic content – our industry’s highest

- 82% desiccant loading – the highest in the industry

- 16-lb. / CUFT optimum density

- >200 KPA mechanical strength

- Low pressure drop

- Water washable

Hub-and-Spoke System's Rigid Structure

- Thick-walled, DOM tubing-machined hub

- Welded 10-gauge spokes

- Welded coupling nut at spoke end

- Welded media retention strip

Flanged Outer Band

- Laser cut for maximum accuracy

- Stainless-steel construction

- Welded seam with bolted attachment

Different Industries and Applications

-

Corrosion Prevention

- Marine drilling rig layup

- Industrial plant layup

- Galvanized steel storage

- Protection box beams in bridges

- Ball bearing storage

- SCR motor control centers

- Generator rotor storage

- Sodium iodide crystal finishing

- Oil tanker layup

- Automotive stampings protection

- Military aircraft avionics protection

- Civil aircraft corrosion prevention

- Calcium metal fabrication

- Metal hydride machining

- Computer storage

- Chemical plant pipe galleries

- Yacht protection

- Canal lock mechanism protection

- Pumping station

- Boiler protection

- Military tanks

- Helicopter storage

- Nuclear waste storage

- Precision tooling storage

- Ammunition storage

- Tire creel rooms and wire storage

- Razor blade manufacturing

- Tritium containment

-

Condensation Prevention

- Optical polishing

- Refrigerated display cases

- Environmental simulation

- Large gear cases

- High vacuum sputtering

- Gumball forming rolls

- Chilled rollers for film casting

- Refrigerated warehouse floors

- Altitude simulation cooling

- Cold product receiving rooms

- Fruit and vegetable storage

- Rock cave storage

- Ice rinks

- Water treatment plants

- Surface preparation and coating

- Injection molding

-

Mold and Fungus Prevention

- Grain storage

- Tulip bulb storage

- Food plant sanitation

- Rope fiber storage

- Historic building protection

- Photographic film storage

- Wooden sculpture preservation

- Fur storage

- Cocoa bean storage

- Dried fish storage

- Mummy preservation

- Wine cellars

- Underground food storage

- Milk powder storage

- Malt storage

- Museum storage

- Summer cottage winter protection

- Winter cottage summer protection

- Fabric and textile storage

- Archival storage

- Seed storage

- Cargo protection

- Breweries

-

Moisture Regain Prevention

- ,Biomedical dry rooms

- Fertilizer packaging and storage

- Pharmaceutical tableting

- Foundry core storage

- Powdered drink mix packaging

- Plastic resin storage

- Instant coffee processing

- Sealed lead-acid battery filling

- Pre-preg material storage

- Flour, plastic and power airveying

- Sugar storage and packaging

- Epoxy powder manufacturing

- Pharmaceutical packaging

- Vitamin tableting and packaging

- Circuit board storage and machining

- Photolithography operations

- Precision color printing

- Cork storage

- Candy tableting and packaging

- Dried vegetable storage

- Propellant mixing and casting

- Missile motor storage

- Contact lens manufacturing

- Filament winding

- Lens coating

- Veneer storage

- Power cable joining

- Insulation for cold tanks

- Fruit powder handling

- Chewing gum ripening rooms

- Candy packaging

- Semiconductor and pharmaceutical clean rooms

- Safety glass laminating

- Advanced composite manufacturing

-

Product Drying

- Uncured honey drying

- Photographic film manufacturing

- High voltage transformers

- Diagnostic reagent powders

- Whey powder

- Instant coffee creamer

- Pharmaceutical powders

- Yeast

- Sorbitol

- Sugar substrates

- Chromatography materials

- Low-moisture welding rods

- Emergency oxygen candles

- PET plastic resin

- Nylon resin

- Expandable bead polystyrene

- Glass powder

- Paint pigment

- Tomato powder

- Cork

- Prosciutto ham

- Hard sausage

- Potato flakes

- Grated cheese

- Pasta

- Cigars

- Seeds

- Wax coated cheese

- Tea

- Gelatin

- Matches

- Onions and garlic

- Milk and whey powders

- Jellybeans

- Breakfast cereal

- Investment casting

- Plastic resin drying

- Candy coatings

- Fish drying

-

Dry Cooling

- Public buildings and auditoriums

- Nursing homes

- Health clubs

- Retail stores

- Hotels and motels

- Office building retrofits

- Supermarkets

- Medical office buildings

- Hospitals

- Sick buildings

- Advanced HVAC systems

Desiccant Manual

Desiccant Software

Call for More Information

Cost-Effective Solutions

(877) 768-6771

(877) 768-6771

Related Dehumidification Products

Learn More About Rotor Source

Reviews

Hi. Do you need any help?

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2025

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.

Share On: